On Line Maintenance

Prodigy's On Line Maintenance helps to schedule preventive maintenance, reduce downtime, improve efficiency and lower operating costs by giving you instant access to important information when you need it.

Fast access to information when you need it

The facility provides a single source of support information for system users, production operators, maintenance engineers etc. It allows instant access to relevant information which can include standard operating procedures, routine maintenance instructions, machine schematics, emergency contact numbers or procedures, training videos and much more. It allows all the information that is usually 'filed away...somewhere!' to be kept in one location, properly indexed and ready for fast access when required.

Although designed to reduce downtime in production processes the facility is also an ideal aid for operator training. With images, documents and video readily available on screen new operators (or infrequent users) can be quickly familiarised with equipment and operating procedures.

The facility has particular value in emergency or critical situations when time is of the essence. Being able to instantly call up the correct information can avert a crisis.

To access the information needed any number of icons or buttons can be placed on displays. Simply click on the relevant icon or button to bring up the right information.

Typically in a production plant "spanner" icons would be placed on screen next to the item of equipment to which they refer. Clicking on an icon will show all the associated files. Any number of information files can be linked to an icon.

| On Line Maintenance icon |

Icons can be hidden from view in normal operation, automatically appearing when Prodigy detects a problem such as a specific alarm condition or incorrect sequence of events.

Store documents, images, sound & video

All common file formats can be easily stored and indexed making it simple to build an on line knowledge base.

Files supported include:-

- JPG & BMP for graphics, images, photographs

- AVI & MPG for video

- WAV for audio

- Plain Text, Rich Text, Microsoft Word for text documents

- PDF (Portable Document Format) for documents, schematics etc.

Automate preventive maintenance scheduling

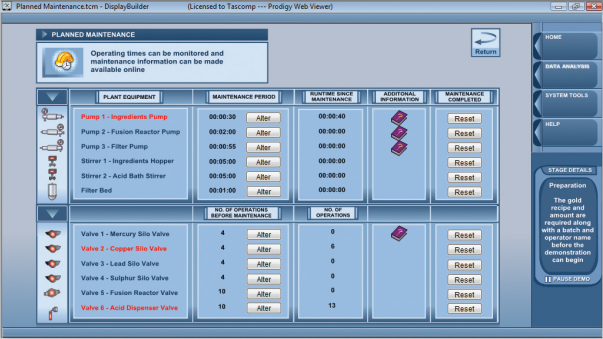

|

| Example of Prodigy Preventive Maintenance display |

To help with the scheduling of preventive maintenance, Prodigy can automatically monitor a wide range of parameters that effect equipment maintenance intervals. These can include run times, number of operations or cycles, time spent under load, total throughput etc.

Using real time data acquisition Prodigy can calculate when any such parameter has passed a predetermined level. It then provides messages via the on screen alarm banner or printed report to indicate that scheduled maintenance is imminent or overdue.

| Example of Maintenance Overdue message on Alarm Banner |

It will even pop up the maintenance icon on the plant display next to the item of equipment that requires maintenance. Prodigy can therefore automate the maintenance schedule and ensures optimum maintenance based on actual equipment usage or workload.

Read an Example Application - Pump Monitoring System

This facility is available up to Prodigy version 8.